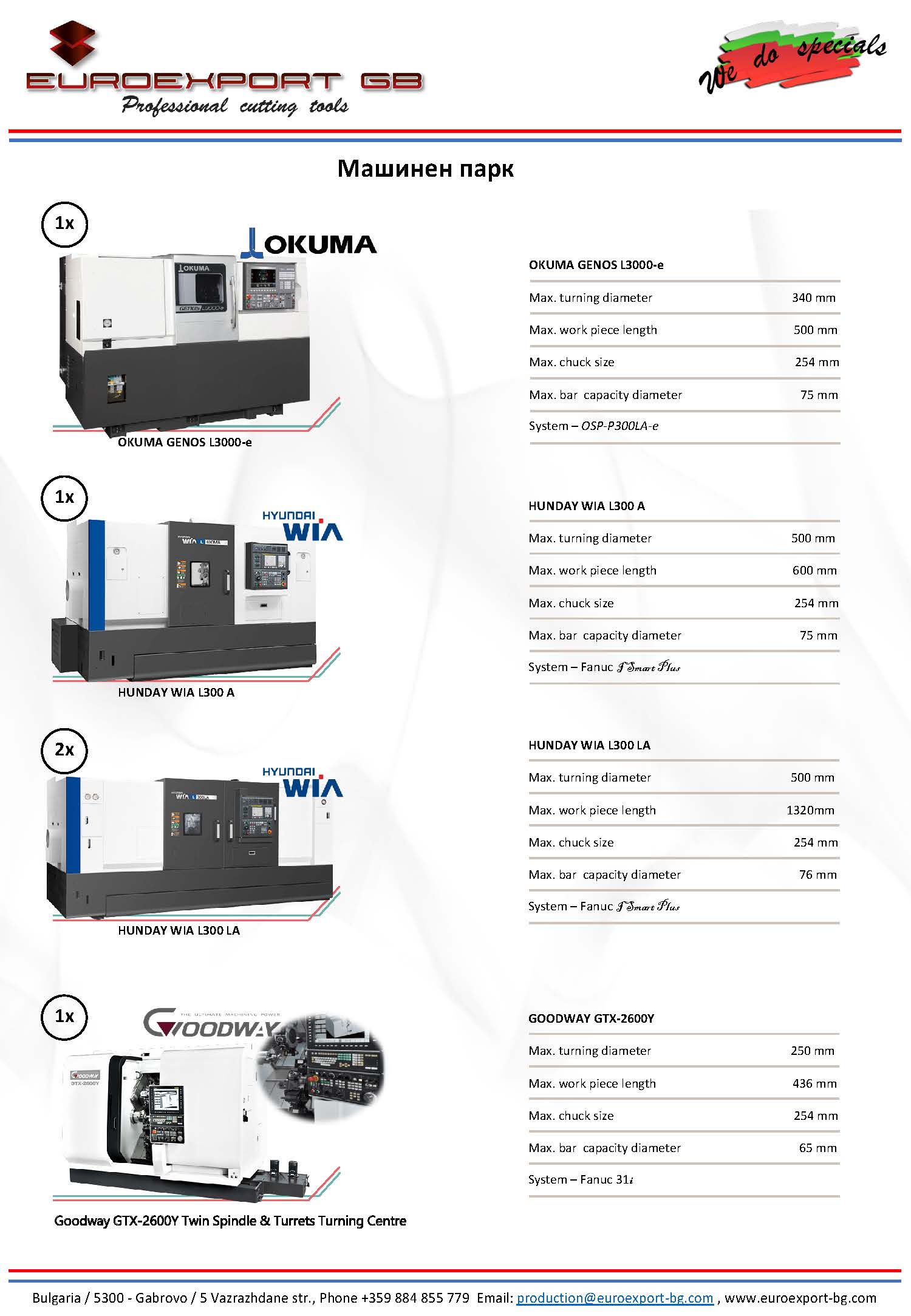

As an additional service company Euroexport GB Ltd. has a scope of machining parts and components on CNC machines and creation, optimization and implementation of technological know-how in the field of machining. We are truly inspired by technology and innovation. Euroexport GB Ltd. is specialized in machining of steels, stainless steels, aluminum, brass, titanium alloys and other “exotic” materials.

Throughout the years Euroexport GB Ltd has proved to be a correct and reliable partner, offering high quality products at reasonable price and by the time fixed in the contract. Our main goal is to achieve a dynamic growth including enlargement of the final production, application of new high technologies and modern machines, constantly improving the quality and the variety of our products as well as expanding our market positions.

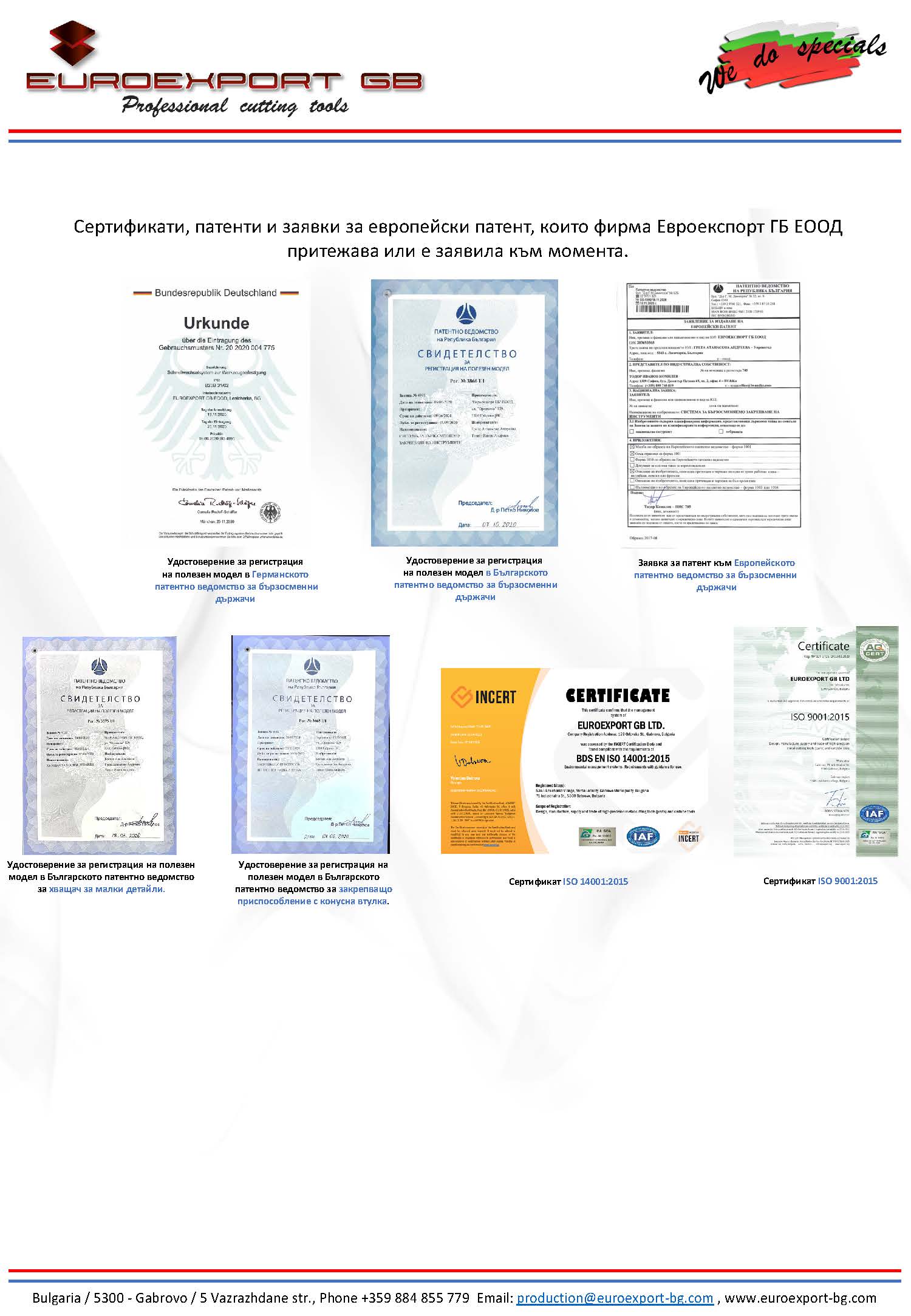

The Euroexport GB is ISO 9001-2015 certifecated by AQ Cert and ISO14001:2015 certifecated by INCERT.

.jpg)

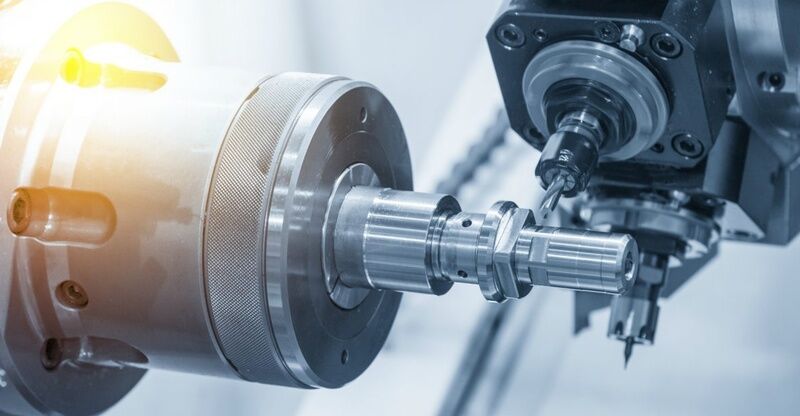

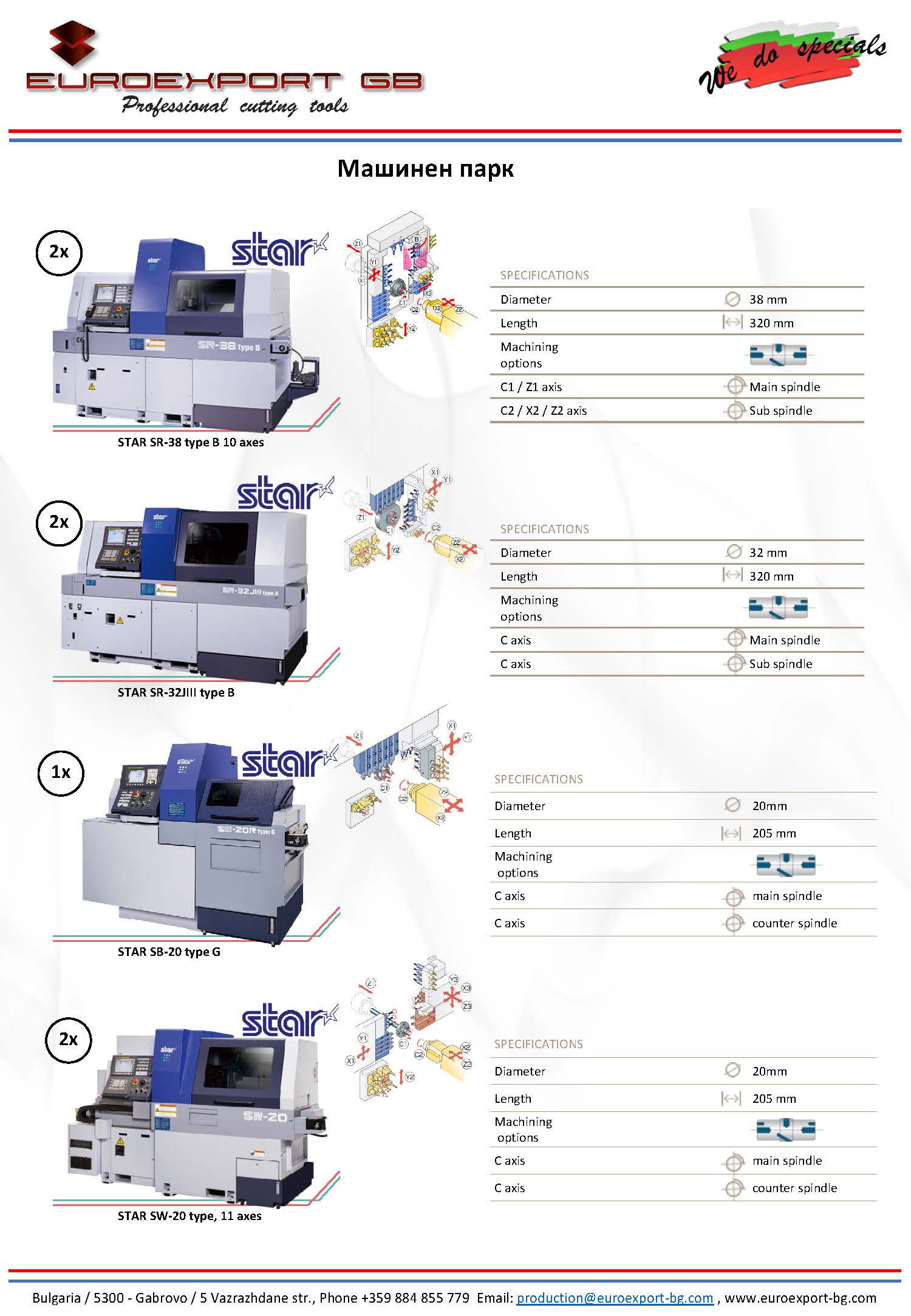

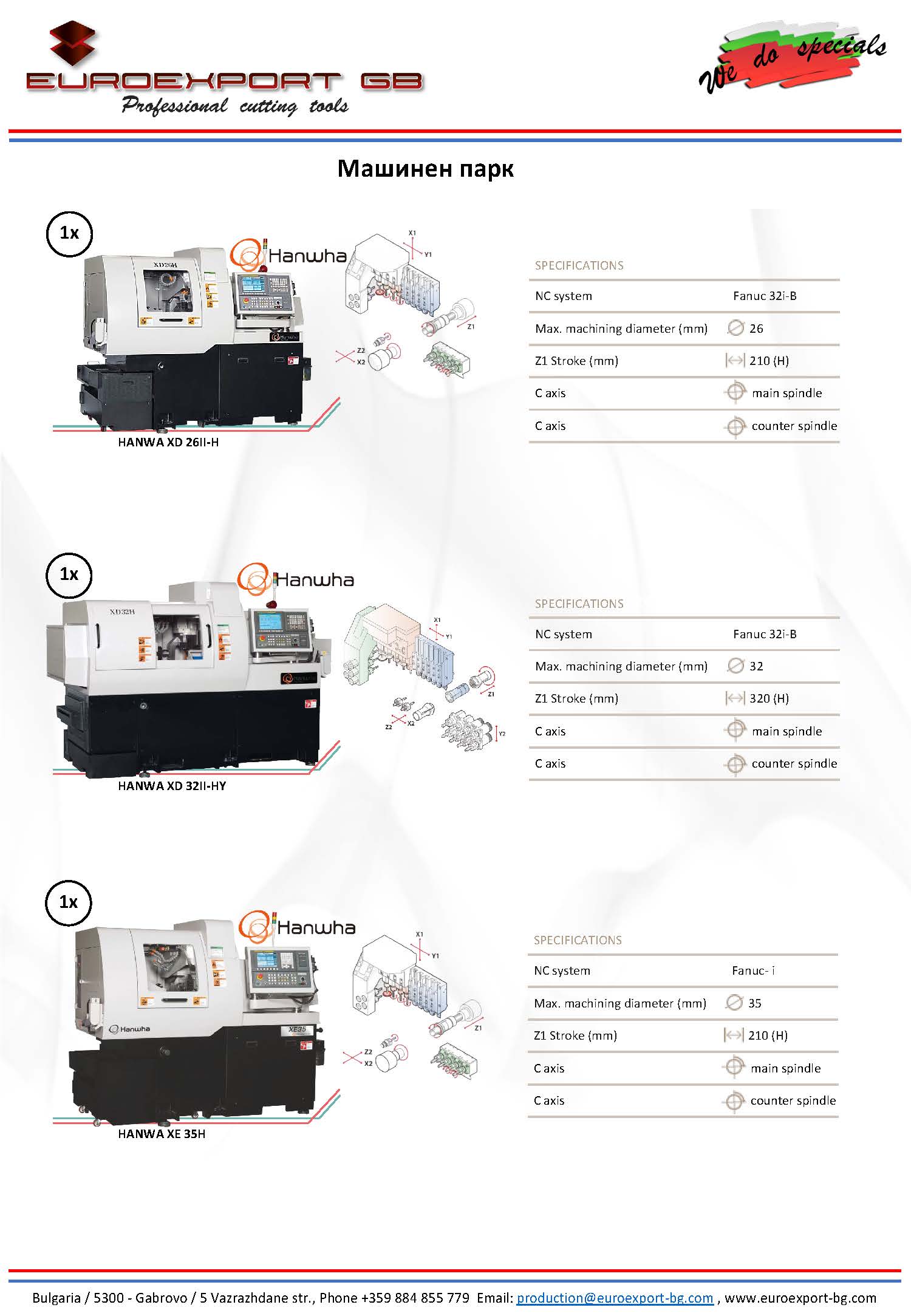

Modern machine park

,

,

,

,