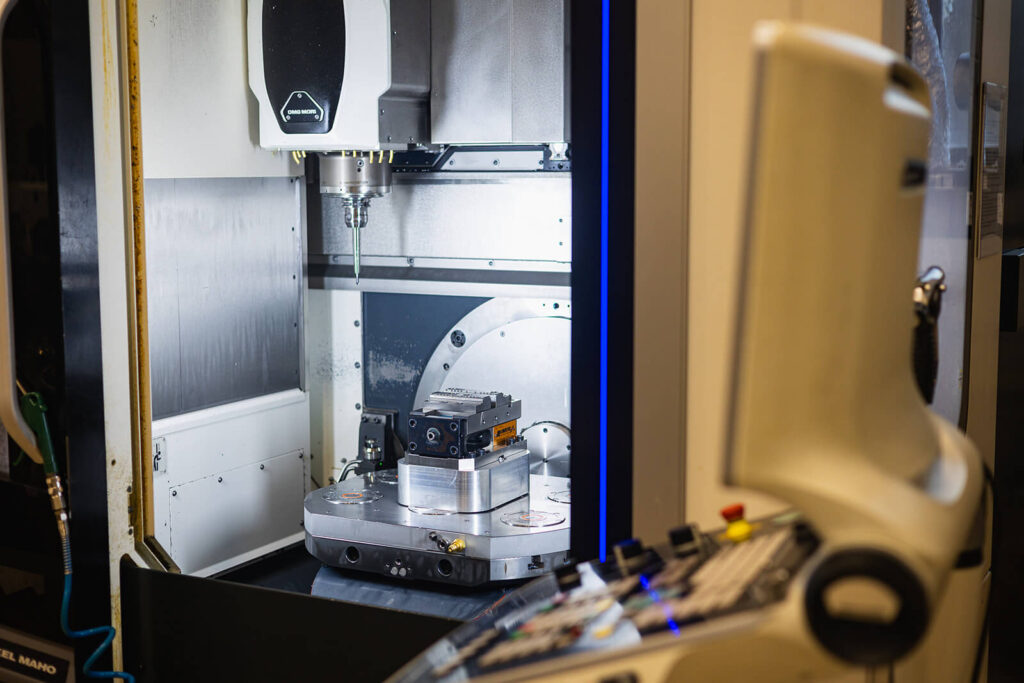

CNC Milling centers.

CNC milling is a machining process that uses computer numerical control (CNC) technology to remove material from a workpiece. It involves the use of a rotating cutting tool to remove material in a precise and controlled manner, resulting in the creation of complex shapes, contours, and features.

Key points about CNC milling

- Precision and Accuracy: CNC milling offers high precision and accuracy, allowing for tight tolerances and repeatable results. This makes it suitable for producing parts with intricate details and complex geometries.

- Versatility: CNC milling can be used with a wide range of materials, including metals, plastics, and composites. It is commonly used in industries such as aerospace, automotive, electronics, and manufacturing.

- Automation and Efficiency: CNC milling machines are automated, which means they can run continuously without constant manual intervention. This leads to increased productivity and efficiency, as multiple operations can be performed in a single setup.

- Flexibility: CNC milling machines can be programmed to produce a variety of parts and components. They can create simple 2D profiles, as well as complex 3D shapes. The ability to switch between different tools and cutting strategies adds to their versatility.

- Cost-effectiveness: While CNC milling machines can be expensive, they offer long- term cost savings due to their efficiency and accuracy. They can reduce material waste, minimize human error, and optimize production processes.

- Design Freedom: CNC milling allows for the production of highly customized and intricate parts. It enables designers to bring their ideas to life by translating digital designs into physical objects with high precision.

Overall, CNC milling is a versatile and efficient machining process that offers high precision, automation, and design flexibility. It plays a crucial role in various industries where complex and precise parts are required.

Design & Manufacturing

SELF-developed special equipment designed for milling centers is the key to unlocking efficiency, accuracy, and versatility, empowering manufacturers to stay ahead in today’s competitive market

- Precision and Accuracy: CNC milling offers high precision and accuracy, allowing for tight tolerances and repeatable results. This makes it suitable for producing parts with intricate details and complex geometries.

- Versatility: CNC milling can be used with a wide range of materials, including metals, plastics, and composites. It is commonly used in industries such as aerospace, automotive, electronics, and manufacturing.

- Automation and Efficiency: CNC milling machines are automated, which means they can run continuously without constant manual intervention. This leads to increased productivity and efficiency, as multiple operations can be performed in a single setup.

- Flexibility: CNC milling machines can be programmed to produce a variety of parts and components. They can create simple 2D profiles, as well as complex 3D shapes. The ability to switch between different tools and cutting strategies adds to their versatility.

- Cost-effectiveness: While CNC milling machines can be expensive, they offer long- term cost savings due to their efficiency and accuracy. They can reduce material waste, minimize human error, and optimize production processes.

- Design Freedom: CNC milling allows for the production of highly customized and intricate parts. It enables designers to bring their ideas to life by translating digital designs into physical objects with high precision.