CNC Turning – Swiss Type and Turning Centers

CNC turning is a machining process that utilizes computer numerical control (CNC) technology to shape a workpiece by rotating it against a cutting tool. Here are some key points about CNC turning:

Advantages of CNC Turning: Precision, Efficiency, and Versatility

- Rotation and Cutting: In CNC turning, the workpiece is clamped and rotated while a cutting tool removes material to create the desired shape. This process is ideal for cylindrical parts, such as shafts, pins, and tubes.

- Precision and Efficiency: CNC turning offers high precision and efficiency, allowing for tight tolerances and smooth surface finishes. It is capable of producing complex geometries and intricate details with ease.

- Versatility: CNC turning can be used with a wide range of materials, including metals, plastics, and wood. It is commonly employed in industries such as automotive, aerospace, and medical device manufacturing.

- Automation and Productivity: CNC turning machines are automated, enabling continuous operation and reducing the need for manual intervention. This results in increased productivity, as multiple operations can be performed in a single setup.

-

Cost-effectiveness: While CNC turning machines may have a higher initial cost, they

offer long-term cost savings due to their efficiency and accuracy. They minimize

material waste, reduce human error, and optimize production processes.

- Quick Setup and Changeover: CNC turning machines allow for quick setup and changeover between different parts, making them suitable for small to medium batch production.

- Design Flexibility: CNC turning can produce a wide range of shapes and features, including external and internal threads, grooves, and chamfers. It provides designers with the freedom to create custom parts and components.

Summary

In summary, CNC turning is a versatile and efficient machining process that offers high precision, automation, and design flexibility. It is widely used in various industries for producing cylindrical parts with excellent accuracy and surface finish.

By using the self-designed, highly efficient tools of our trimline NEXXTOOLS we are taking machining and efficiency of the process to a higher level. Constant improvement of cutting technology and parameters is our specialty and by that we guarantee the best performance.

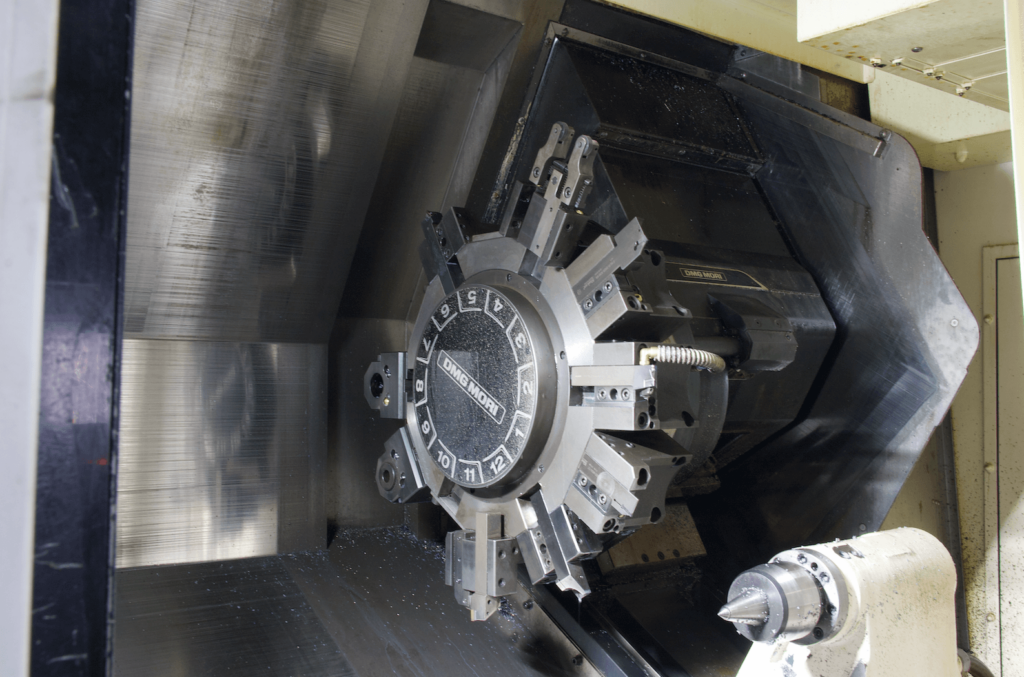

Swiss type technologies

- Higher manufacturing speed

- CNC path Excellence

- Work Stability

- Repeatable quality during High volume series

- Profile tooling

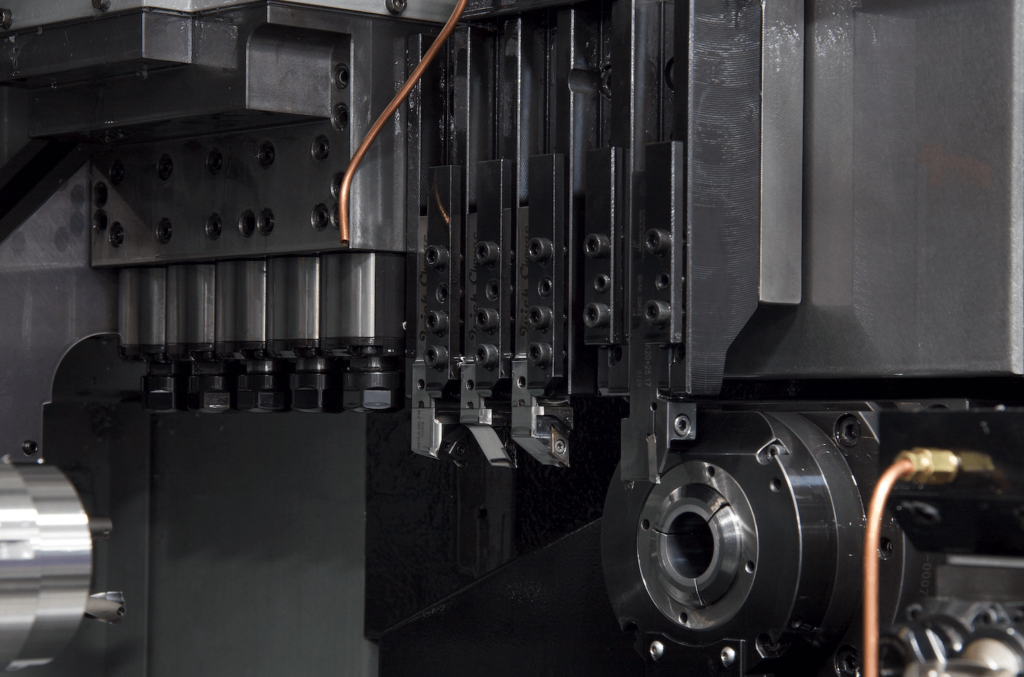

Turning Centers

- Long & Big diameter parts

- Easy load / unload

- Large number of tooling positions – Two turrets

- Two spindle type machinery